Industrial Heat Pump

Net-zero emissions, electrified

Industrial steam

heat pump boiler

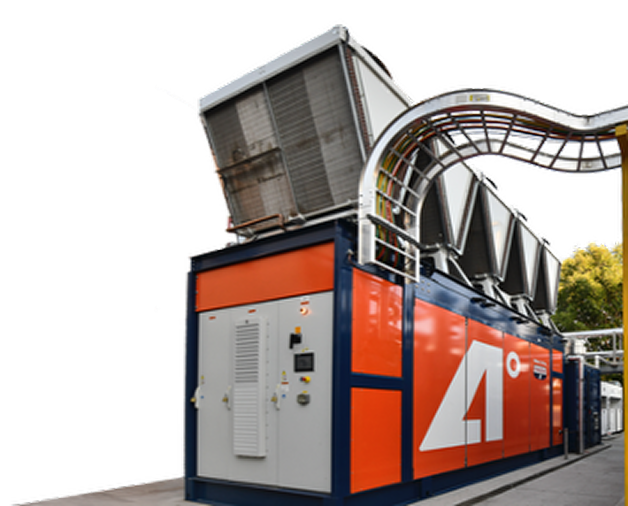

Boiler 2.0 is an air-sourced steam-generating industrial heat pump based on cascaded vapor compression cycles. It was designed as a drop-in replacement for existing gas-fired steam boilers, negating the need for expensive and complex waste heat integration.

The first generation of Boiler 2.0 is a system capable of producing one ton of steam per hour, requiring only the heat of outside air, boiler feedwater, and electrical power.

Photo by Dennis Schroeder

AtmosZero Boiler 2.0 is designed as a modular electrified boiler with zero on-site carbon, NOx, SOx, and PM emissions

Boiler 2.0 General Specifications

121–153°C | 1.0–4.1 bar(g), 250–307°F | 14–60 PSIG

| Heat Pump Basic Configuration | EU Specs | US Specs |

|---|---|---|

| Nominal duty | <=1 MW thermal** | <= 3412 MMBtu/hr** |

| Chilling capacity (optional) | > 350 kW thermal** | > 100 tons** |

| Voltage; current | 400 V (50 Hz) | 480 V (60 Hz) |

| Output flow | <= 1531 kg/hr saturated steam | <= 3376 lb/hr saturated steam |

| Output temperature/ pressure | 121°C / 1.0 bar(g) to 153°C / 4.1 bar(g) | 250°F / 14 PSIG to 307°F / 60 PSIG |

| Heat source | Air or liquid source | Air or liquid source |

| Heat source temperature | −20°C to 40°C | −4 to 104°F |

| Footprint | 2.4 x 8.2 m | 8 x 27 ft |

| Refrigerant | Ultra-low GWP, low flammability, low toxicity options available | Ultra-low GWP, low flammability, low toxicity options available |

| Sound level | Sound pressure level < 77 dB(A) at 0.5 m |

Sound pressure level < 77 dB(A) at 0.5 m |

Plug-and-play industrial steam solution that installs in days and generates instant results

• Air coils draw low-temperature heat from the outside air

• A core heat pump, consisting of two cycles in cascade upgrading low-temperature heat to 153°C

• Optional: Mechanical vapor compressor (MVR) to upgrade the steam pressure, enabling steam temperatures up to 165°C (first product), and 200 °C (roadmap)

While the system allows compact placement as a fully self-contained unit, a split configuration in which the air coils are placed away from the core heat pump is possible.

Boiler 2.0 was designed to be application-agnostic and can be used in various applications. However, initial market interest has been significant within the food and beverage and chemicals industries.

Due to the optimized cycle design and the use of high-efficiency centrifugal compressors, a high COP can be reached.

Compliance

Please contact AtmosZero for information on compliance provisions for your specific region.

*Dependent on temperature of the source heat and steam pressure being delivered

**Dependent on feedwater temperature